Many people dream of a comfortable room where they don’t have to constantly turn on/off the heater (convector) or open a window for ventilation. To do this, it is enough to install an air thermostat. He will make sure that the temperature in the room is comfortable for you. Thermoregulators are quite convenient to use, there are sensory models, and there are mechanical ones, you can easily match the design of any room.

The programmable thermostat is in fact part of the smart home system!

How to install a programmable thermostat

To install a programmable thermostat, we need stripping pliers, wire cutters, a screwdriver with an insulated handle and a drill.

Before starting work, turn off the electricity at the main switch!

Wire selection

Choose the standard color of the wire according to its purpose, and the wire section according to the purpose of the lines of group networks (lighting, sockets).

Earth is only yellow-green.

Neutral is only blue.

Phase - red, black, brown, purple, orange.

All lines of group networks, without exception, including lighting lines, must be equipped with a ground wire!

Often the thermostat is placed in the bathroom along with.

Programmable thermostat power

As a rule, the protection of thermostats is triggered when a current of 5 A is received (at a maximum power of 1100 W).

If you have electric heating (by convectors), then you must compare the sum of the convector capacities that you want to connect to the programmable thermostat with its breaking capacity. If the total power is less than 1100 W, you can safely connect them to a programmable thermostat. If the sum of the outputs is higher, then you must connect the convectors via a power switch.

At what height should the thermostat be hung?

The thermostat is hung at a height of 1.5 m in an accessible, protected from heat sources (fireplace, direct sunlight, convector) and drafts (windows, doors).

Important: the thermostat is powered by batteries, there are no batteries included!

After connecting the heaters to the thermostat, it is connected to the electrical network.

We want to make a warm floor in the bathroom and in the kitchen, the premises are located nearby. Is it possible to connect two separate underfloor heating circuits to one controller? Are there any thermostats?

Yes, there is such a thermostat - this is I‑Warm 730

I‑Warm 730 allows you to control two underfloor heating circuits separately, in fact, these are two TP 715 in one housing. I‑Warm 730 is installed in a standard one and a half box, two floor temperature sensors and two mats (cables) are connected. It does not have automatic shutdown settings, like the TP 725.

To what temperature will the regulator heat the floor?

If we talk about electronic thermostats TP 715 and TP 725, then the temperature setting range is from +5 ° C to +45 ° C (usually t max is no more than 33 ° C).

If you are interested in a high temperature, then only a cable (not mats) with an increased rated power will do, but walking on such a floor will no longer be comfortable and hot ...

As for the mechanical thermostat TP 115, the adjustment scale on the front panel is rather arbitrary, and when setting up, you have to rely more on your own feelings than on the exact readings of the device. The thermostat, according to the technical data sheet, allows you to set the floor temperature +5 °C ... +45 °C.

Based on practice, it can be seen that in an ordinary apartment, the floor temperature range will be from room temperature t ° C to +33 ° C; and the lower the heating temperature, the more economical the energy consumption...

Differences of thermostats

On the front panel of the TR 115 thermostat are located:

- power key;

- adjusting temperature wheel;

- floor heating LED.

The thermostat works on the principle of a refrigerator, that is, it heats the floor to the set temperature - it automatically turns off the heating, the floor cools down by 2 ... 3 ° C, the controller turns on the heating again ... This is the mode of maintaining a constant floor temperature.

Unlike electronic thermostats TP 715 and TP 725, TP 115 does not require the user to study the instructions to manage the settings and is the most economical model in terms of price, it allows you to reduce energy costs by up to 30%...

The electronic thermostat TP 715, unlike the mechanical TP 115, has an LCD display on the front panel, it displays:

- floor temperature;

- air temperature in the room.

TR 715 has the following functions:

- self-diagnostics - when the cable or sensor exits the operating mode, information is displayed;

- protection mode (if the sensor breaks, it is not necessary to change it immediately, but you can set the system to work on time, where 100% is taken as 1 hour and the floor work is set as a percentage, for example, at 50% the floor will heat up for 30 minutes, and the next 30 minutes - cool down).

The TP 715 works in the same way as the TP 115, maintaining a constant floor temperature on the principle of a refrigerator or an iron, that is, it heats the floor to the set t ° C, then automatically turns it off, then cools down by 2 ° ... 3 ° C turns it on again .. .

Unlike the TP 725, there is no possibility of programming by time and day of the week, although outwardly they look the same.

Both thermostats have an LCD display and look very similar.

TP 715 you set a certain floor temperature in degrees, the warm floor starts to heat up and when this temperature is reached, it turns off, cools down for a while and turns on again.

You can program TP 725 in the way that suits you... For example, if you go to work 5 days a week, you can program the regulator so that it heats the floor only in the morning, before you wake up, and turns off automatically after leaving, and in the evening it will heat the floor, and at night, when the warm floor is not needed, it will turn it off again. And on weekends, you can program the warm floor for the whole day if you are at home, or, conversely, to completely turn off when you leave for the country ...

You cannot program TP 715.

TR 725 is a more economical regulator in terms of electricity consumption (up to 50% and up to 70%, respectively).

Which of the Teplolux regulators is more reliable?

All temperature controllers are absolutely reliable, the manufacturer gives a 2-year warranty for all controllers, fault-tolerance testing with special equipment showed that the trouble-free service life at full load is at least 6 years.

When choosing, it is necessary to proceed, to a greater extent, not from the requirements for reliability, since this parameter is the same for all regulators, but from the tasks set:

TP 115 allows

- turn on or turn off the warm floor at any time;

- set the desired temperature with the wheel;

- The LED indicates the status of floor heating.

- It controls the floor temperature, like TP 115 - heats the floor to the set temperature, turns off the power, cools down by 2 ... 3 ° C and turns it on again.

- Information on the LCD display about the current, desired and indoor air temperature of the floor.

- Self-diagnosis function - if any element of the circuit fails, a warning appears on the screen.

- The ability to work in protective mode (if the floor temperature sensor breaks down, it is not necessary to change it immediately, you can set the system to work on time, where 1 hour is taken for 1 unit and the work is configured in % of the hour).

TP 725 has all the functions of TP 715 and outwardly practically does not differ, but there is an extra. programming function:

- Possibility to set the operation of the warm floor for each day of the week according to your program. This is convenient if you go to work 5 days a week, and you need a warm floor only in the morning and only in the evening, and on weekends, if you stay at home, then it works all day, or if you go to the country, it doesn’t work at all ... This is convenient also with a two-tariff payment for electricity, when the floor heats up during the night and cools down during the day.

- The statistics menu informs you about energy savings.

At what height from the floor should the thermostat be installed?

The instructions indicate that it is 1 m. Can it be installed higher or lower? And is it necessary to make a connection through the junction box?

The temperature controller, regardless of model, can be installed at any height from the floor.

There are no restrictions on the length of the floor temperature sensor: the factory length of the wire is 2 m, but if it is not enough, you can extend it with an ordinary copper wire (2 × 0.75) up to 50 meters.

The video instructions for installing a thin warm floor say about installing a thermostat at a height of 1 m from the floor - this is just an example, if you want to install the regulator at a different level, then there are no restrictions, install where you like ...

It is advisable to connect through the junction box only if the thermostat is located far enough from the place where the temperature sensor is laid. In the event of a sensor failure, it is much more convenient to change it from a nearby junction box than to try to push a soft wire along a corrugated tube inside the wall through the entire apartment, and even with several bends.

If the thermostat is located close to the place of laying the sensor (2 meters or less), then when replacing it, it will be enough to unscrew the controller from the wall, pull out the temperature sensor and insert a new one, no extra hole in the wall with the junction box is needed in this case.

Can the regulator be installed in a standard socket?

Yes, it is in a standard single box with a diameter of 68 mm that thermostats are installed, except for TR 730 - it is placed in a one and a half box (oval shape).

Underfloor heating is a rather complex, well-functioning system consisting of a heating element, the coolant in which, depending on the type, can be electric current or hot water. Electric underfloor heating is the most popular. Installation of this type of system involves the installation of not only wires that will give off heat, but also a thermostat. An underfloor heating sensor is also installed.

The temperature sensor is one of the most important elements that make up the floor heating system. It is a copper conductor covered with insulating material, the end of the sensor in order to protect against various external influences is closed with a special cone. The principle of operation of the device is simple: the sensor independently determines the temperature of the floor (when heated, the resistance of the device decreases) and then reports the information received to the thermostat.

Further, the thermostat, depending on the received data - high or low temperature - automatically turns on / off the floor heating system. Typically, the device is triggered if the temperature drops below the set mark by only 0.5 degrees. In general, the frequency of the “on-off” cycle depends on several factors - this is the thickness, type of coating, the temperature of the air in the room, the presence or absence of insulation.

On a note! The temperature sensor can be located at different distances to the temperature controller. Its informativeness in this case practically does not change.

Thus, these devices - both the sensor and the regulator - help to create a favorable microclimate in the room, controlling the entire underfloor heating system.

Features and benefits of use

The installation of a temperature sensor and thermostat in the underfloor heating system is optional. But experts strongly recommend not to neglect them. The presence of these small but important devices is necessary for the correct operation of the heating. The fact is that the absence of a temperature sensor will not allow you to control the temperature of floor heating, which can adversely affect the condition of the floor covering as a result of violation of operating conditions.

For example, laminate and carpet should not be used under high temperature- the permissible heating rate of the coatings is only +30 degrees. When exceeded, both the laminate and the carpet begin to release compounds into the atmosphere, which can have Negative influence on human health. Also, the laminate is prone to deformation with significant overheating of the lamellas. If a temperature sensor is installed in the system, then when a certain temperature is reached, the floor heating is turned off, and nothing threatens the coatings.

Also, the device helps to control the cost of electricity, which means it saves a lot of money that goes to pay utility bills.

Types of temperature sensors for underfloor heating

The choice of a temperature sensor that is suitable in a particular situation must be approached with all responsibility. And first you need to study what types of these devices exist.

On a note! In most cases, sensors for underfloor heating come with thermostats, which facilitates their installation and configuration.

Table. Types of sensors for underfloor heating.

| Type of | Characteristic |

|---|---|

| Such a sensor is installed where there is no wind and draft, and also where it will not be exposed to sunlight. Otherwise, the instrument readings will be inaccurate. This type measures the temperature of the air around it. |

| Mounted directly on the surface to be heated. |

On a note! There are types of thermostats that are immediately equipped with two temperature sensors. It is believed that such a system is much more reliable in operation than a conventional one.

Functions and choice of thermostat

The thermostat is also a very important device that is used when installing a floor heating system. It will process the indicators that the temperature sensor transmits to it, and, depending on them, control the system.

Thermostat functions:

- heating system control;

- control and maintenance of optimal floor temperature;

- process of control of the spent electric power;

- optimization and improvement of floor heating.

On a note! The energy consumption of the entire system usually corresponds to ½ of its capacity. Thus, it is possible to calculate the approximate costs.

Table. Types of thermostats.

| Type of | Characteristic |

|---|---|

| The simplest type of device and affordable. Its main working element is a special metal plate, it reacts to temperature changes. When the system cools down, as soon as the curvature of the plate becomes such that it touches the second contact, the system is turned on. The specific value of the floor heating temperature will not allow you to set the device. |

| The device works like this: it is equipped with a special element that generates a special signal. Power directly depends on the ambient temperature. Such thermostats allow you to set the exact heating temperature, sometimes even to fractions of a degree. The device is controlled using buttons and a small display. More expensive and more difficult to manage than the previous ones. |

| The most expensive type of temperature sensor, but it allows you to set certain parameters, upon reaching which the thermostat will turn the entire system on or off. Such a device will allow you to create a microclimate in the apartment that is suitable for a particular person. At the same time, the programmable thermostat can be configured in such a way that it starts the system at a strictly allotted time. That is, it can heat the floors immediately before the owner arrives at home, without wasting electricity during his absence from the room. However, it is not advisable to use it in the bathroom. |

Experienced craftsmen recommend installing a programmable thermostat during installation. The cost of it will quickly pay off during the heating season, when electricity bills will increase several times compared to the warm season.

There are also temperature controllers with a limiter. This type of device is triggered depending on the maximum / minimum allowable temperature. Its main function is to prevent the floor from overheating or getting too cold.

There are regulators and alarms. If the sensor detects overheating of the coating, the device will report the violation to the owner of the house using a special signal.

Pros and cons of thermostats

Undoubtedly, the use of a temperature sensor and a thermostat is in itself a big plus for the operation of the entire underfloor heating system.

However, each type of device has its own advantages and disadvantages.

- Advantages electromechanical devices- versatility, ease of use, high reliability and low cost. In addition, if necessary, this type of device is easy to repair or replace on your own. The main disadvantage is the need to manage the system manually. It does not react to the ambient temperature.

- Electric thermostat(together with the sensor) is equipped with a display showing the performance. Also, its advantage is the ability to set accurate temperature values.

- Flaws programmable thermostat– high price, difficulty in operation. But on the other hand, you can even control some models using your phone or computer.

In each individual case, the most convenient thermostat can be used. For example, in order to save money, electromechanical devices can be used in a bathroom, toilet and other small rooms and where a person is not located for a long time. But programmable ones are the best option for living rooms, children's rooms, bedrooms.

Floor temperature sensor and controller - how to choose and install

The choice of temperature sensor and thermostat for installation in the underfloor heating system should be done correctly. Here it is important to evaluate the main indicators and requirements for operation.

On a note! There are types of thermostats that can record data from sensors located in two zones (rooms) at once. Sometimes it is advisable to purchase just such devices.

Choosing a floor heating sensor depending on the floor covering

Depending on the type of floor covering, certain types of sensors should be used. There are the following types of device.

- Fits under soft cover(carpet, linoleum, parquet, laminate). The sensor in this case is a small cylinder attached to the end of a special cable. It is mounted only after the concrete screed has completely dried, in which a small groove is then made specifically for the device.

- Installed under hard floor. A larger element has a special gel shell that protects the device from shock and mechanical damage.

Mounting the thermostat and sensor

The installation of these two devices is quite simple and, as a rule, even beginners do not have any problems if they act in accordance with the instructions. There are two ways to connect the temperature sensor.

- Directly. In this case, the heating cable itself is combined in one bundle with a thermostat.

- Using a junction box. In this case, one cable is laid from the thermostat to the junction box, and then another cable is laid to the heating element.

To connect the temperature control system, you should organize a separate line from the electrical panel. For this, copper wiring with a cross section of 2.5 mm 2 is perfect. Further, a groove is cut in the wall, into which the corrugations with the wire from the temperature sensor and the heating cable will be laid.

Step 1. The wire, at the end of which a temperature sensor is installed, is pushed into a corrugated tube of a suitable diameter.

Step 2 The sensor wire also exits from the other end of the corrugation.

Step 3 The end of the tube, where the sensor itself is located, is closed with a special plastic plug. This is necessary so that nothing gets there, including the building mixture with which the system will be poured.

Step 4 The end of the tube with the sensor is fixed between the two heating circuits right in the middle. It is fixed with a plastic clamp or a special tape. In this case, the installation location of the sensor is chosen so that it is relatively close to the thermostat itself, it is desirable that there is a possibility of relatively easy access to the sensor. The optimal distance from the device to the wall is 50-60 cm.

Attention! The temperature sensor should not be located close to heating appliances or fireplaces, stoves. Otherwise, there will be errors in the readings.

Step 5 The tube from the location of the regulator is led to the floor in a special grooved groove. Its bend at the floor should not be sharp - at least 5 cm.

Step 6 The groove in the wall after laying all the wires and the corrugated tube in it is sealed with cement mortar.

Step 7 The wires need to be tinned.

Step 8 After that, the wires are connected to the thermostat. The regulator is installed in its place - a hole in the wall above the groove for the wires.

Step 9 All electrical connections are checked and then the underfloor heating system is turned on for one minute. This will allow you to check its performance.

Step 10 If everything works, then the signal light on the thermostat panel will light up, and the floor system will also heat up. On the sketched diagram of the warm floor, the installation location of the temperature sensor is indicated.

Video - How to connect the floor system to the thermostat

Video - Installing a temperature sensor

Temperature sensor replacement

If the floor heating temperature sensor is out of order, then it will have to be replaced. Otherwise, the thermostat will not be able to control the heating system. The cause of the breakdown will help to find out the diagnosis by the tester. As a rule, it identifies two causes of a malfunction - both of them are associated with contacts (either it is where it is not needed, or it is absent where it is needed).

The first step is to test the input wires - for this you will have to disassemble the regulator housing. When the power is on, the tester checks for voltage in the wires. If there is no power, then one of the switches does not work - then the operability of the devices in the network is checked up to the place where the regulator is installed. If there is voltage at the input contacts, then the test continues at the output. The wires of the thermal circuit are disconnected from the regulator when the current is off. If in this case, when the energy is turned on, there is no voltage on the output wires, then the breakdown is hidden in the control unit or in the sensor itself. The resistance of the sensor is checked with an ohmmeter. If the sensor does not work, it must be dismantled if possible and a new one installed.

Attention! The sensor cannot be repaired, it can only be replaced with a new one. In this case, you will have to buy a new regulator.

What to do if the sensor is not installed

Using an underfloor heating system without a temperature sensor is risky - you can ruin the floor covering. There are several ways to solve the problem.

- Equipping the system with an air sensor (installation is possible only for a cable heating system. The power of the heating circuit must be equal to 170 W / m 2).

- Installation of the sensor in the screed (it is necessary to grind the floor with high precision in order not to damage the heating system).

During the installation of the underfloor heating system, installing both the temperature sensor and the regulator is quite simple. It is more difficult to carry out work if the devices were neglected at one time, and then they realized that they were still necessary. Fortunately, everything is fixable.

The underfloor heating system consists of two elements: a heating circuit and a temperature controller. Moreover, the regulators of underfloor heating can have several more names: thermostats and thermostats, as they are responsible for maintaining the same (static) temperature.

Functions and Benefits

The main function of a thermostat for underfloor heating is to maintain the set temperature. This is achieved by turning the heating elements on/off. It turns out that the underfloor heating controller saves electricity, because the system turns on only periodically when the controlled temperature drops. Therefore, in the presence of such a device, heating is more economical, and, despite the fact that the device is not cheap, it pays off in a period of several months to one year (depending on the cost of the chosen model).

Infrared warm floor under the laminate was laid by many. According to reviews - it warms perfectly

There is another plus to this solution - if the sensor is working properly, the heating elements will not overheat, which will increase their service life and prevent the failure of the heaters due to excess temperature.

The system can also work without a thermostat. But then the functions of this device will have to be performed by a person: turn on / off the heating as needed. With such a device, comfort will be lower, and there will be no savings. In addition, there is a risk of burning the heating cables if you forget or do not turn off the system in time.

Types of thermostats

The floor temperature controller can be of three types:

It is clear that the more functions and capabilities the underfloor heating controller has, the more expensive the device. And how much you need these functions is up to you. But we can definitely say that it is not advisable to use floor programmers for a bathroom or kitchen, because they are visited regardless of the time. Therefore, the ideal way out here is mechanical or digital devices. Moreover, when installing the system in a bathroom or pool, the thermostat is placed outside it: they do not tolerate high humidity, in the kitchen, pool, etc. splashes must not reach the device.

What you don't have to do is to use one control device for two different rooms. For example, it is undesirable to combine a bathroom and a kitchen, although usually the capacities allow this. Simply in this case, you will have to set the general temperature for the two rooms. And if you set the one that will be comfortable in the bathroom, then it will be clearly hot in the kitchen. If you put "in the kitchen", then you will freeze in the bathroom. And so with almost any room. If, nevertheless, there is a desire to use one thermostat for underfloor heating for two rooms or two circuits, then you need to use two-channel models that allow you to control both circuits independently.

Types of floor heating sensors

Different models of thermostats can control the temperature of the floor or air. It depends on the type of sensor that is compatible with the device. The choice of sensor type depends on the function of the heating. If the system is additional and its task is to increase comfort, a floor temperature sensor is used. After all, another system is responsible for air heating in this case, and the task of water or electric heating is to create and maintain a comfortable temperature only under your feet. This floor thermostat sensor is remote. It is connected to special terminals on the case. The control element itself is located at the end of the electric cable; when laying, it is located in the middle between the turns of the heating element on the floor at a distance of at least 50 cm from the wall.

Underfloor heating sensors are a small device at the end of a long cable. It is wound into a piece of pipe fixed to the floor, which is located between the heating elements

If the heating elements are installed in, then the floor heating sensor is placed in a solution, but only in a pipe or corrugated hose. Then, in the event of a breakdown, it will be easy to replace it by simply disconnecting it from the terminals and pulling the wires, then you will need to insert a serviceable one and connect it. When installing a sensor for film underfloor heating, it is not necessary to place it in a pipe. Since with this type of heating there is no screed and, if necessary, it can be replaced by disassembling part of the floor covering. Although, it is still more expedient to spend a little more time during installation and make a strobe under the pipe for the sensor than to disassemble / assemble the entire structure for each replacement.

In the event that a warm floor is the main heating system, a sensor is required that monitors the state of the air. Most often, these sensors are built into the body of the thermostat for underfloor heating. There are also models that work with two sensors at the same time. In both cases, when choosing a place for installation, it is necessary to take into account that it is this device that determines the air temperature. Therefore, it must be positioned so that the sun's rays do not fall on it (they will heat the case, and the temperature will be determined incorrectly). It is worth avoiding those places where there are drafts. They will also affect the measurements of the state of the air, but in the other direction - underestimate the real indicator. Also, devices and devices that actively generate heat should not be nearby.

Installing a thermostat

Installation of equipment should take place at air temperatures from 0 o C to +45 o C. The floor temperature controller is located on one of the walls at a height of 0.4 m to 1.7 m. It must be placed so that direct sunlight, splashes and drafts do not fall on it. When choosing a height, please note that if there are small children in the family, then it is advisable to place the device at a height where it will not be accessible to children: they are very attracted to the buttons / screens / wheels. Therefore, it is better to install in a place inaccessible to children.

According to the installation method, there are two types of thermostats for underfloor heating: overhead and mortise. Under the mortise, you need to make a hole in the wall and install a standard mounting box there - most models fit perfectly in it. Overhead are attached directly to the wall surface and do not require additional work, but they do not have the most attractive appearance.

To provide protection against short circuits and to prevent electric shock, an RCD and / or a circuit breaker is installed in front of the floor thermostat. See the diagram, the dotted line indicates the neutral connection for a two-wire network. RCDs can not be installed everywhere, but in rooms with high humidity, their installation is mandatory. Since in this case there is a lot of equipment, it makes sense to hide everything in a wiring closet. Please note that only people with appropriate training may work on the power supply. Therefore, if you install a thermostat for a warm floor with your own hands, but there is no appropriate preparation, then be sure to invite an electrician for this part.

After installing the mounting box in the wall towards the floor, it is necessary to make strobes for laying the leads of the heating elements (cables, mats or films). A pipe / corrugated hose is placed under the floor temperature sensor in the same groove or in a strobe nearby. There may be only one groove. Then it is made wide enough so that you can easily place all the wires and the pipe. It is possible to make a separate channel for the wires of each heating circuit, and sometimes they are also laid in pipes / corrugated hoses. In this case, the repair will be easier - pull out the wires from the non-working circuits, after disconnecting them from the thermostat, and insert others from the working circuit in their place. And you don't have to hit the wall.

Installing a floor heating sensor

The gate for the sensor goes along the wall to the floor level, and then along the floor at a distance of at least 50 cm from the wall. Moreover, in order for the measurements to be correct, it is desirable to place the control element in the middle between the heating elements, and not near one of them. Lay a pipe or hose in the groove (as recommended by the manufacturer). Lead one end into the mounting box, and securely isolate the second one, the one that will be in the floor, so that the solution does not get into it. You can use electrical tape by winding it in several layers, make a foam plug, etc. After fixing the hose / pipe, insert the floor temperature sensor into it: just lower it into the corresponding hole.

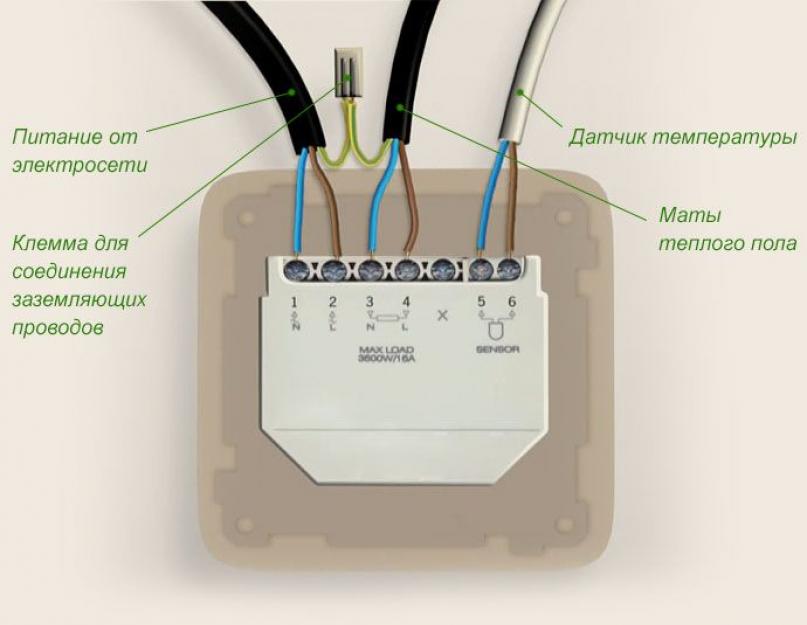

Connection

After the heating elements (, mats,) are laid, the wires from them are led into the mounting box, where the thermostat for the warm floor is installed. Then, according to the scheme that is on the case on the back of the device, all the wires are connected. Only after that is the food supplied.

Now it is possible to carry out a test run (before pouring the screed or laying the flooring) to make sure that the system works. To do this, after checking the correct connection of the wires and the reliability of their fastening, set the lowest temperature, turn on the RCD. Then set the thermostat to 30 ° C (maximum temperature according to SNiP). If the system is operational, a click is heard - the relay has connected the circuit to work. After a few minutes, all parts of the heating elements should be warm. Now, if the temperature is again set to the minimum, you should again hear the click of the power off. After this check, we can assume that the installation of the underfloor heating thermostat is completed and you can start pouring the screed or laying it.

If the system does not turn on, the problem is most likely with the sensor. This is generally a fairly common phenomenon - its failure. So don't be scared. They cost a little, they change easily. To check the serviceability, measure the resistance of the floor heating sensor. The received data is compared with the passport data. There is a difference - the sensor is faulty. You take out the broken one, insert a new one, test everything again. Should earn.

Results

Installing a thermostat and a floor heating sensor is not the most difficult task, it is quite possible for self-assembly. The only difficulty is connecting the power supply and grounding / grounding. For these works, it is advisable to invite an electrician. You can do the rest of the installation steps yourself.

Then you need to get all the necessary information about temperature sensors in the first place.

The temperature sensor is an indispensable element for optimal operation of the electric underfloor heating. In addition to temperature control, it allows you to reduce energy costs.

The figure clearly shows the location of the electric floor heating sensor

A warm floor sensor is a copper wire protected by a special flask that determines the temperature of the air or floor, then transmits this data. A plus is that the length of the wire can be adjusted - it is possible to reduce the wire and extend it to a maximum of 50 meters.

As the floor temperature increases, the resistance of the sensor decreases. The thermostat, having received information from the temperature sensor, begins to react and either turns on or off the warm floor, taking into account the set temperature. Maintaining a certain temperature occurs as follows: when the desired setpoint is reached, the system turns off, and as soon as there is a decrease by half a degree, the heating starts again.

If the sensor breaks, it must be completely replaced. The main thing is that the replacement process takes place without errors, otherwise the system's response to a decrease in temperature worsens, and the interval before turning on the floor can reach 5 degrees.

Sensor selection

When choosing a floor heating sensor, which can be sold separately or bundled with a thermostat, it is worth considering some factors:

- Sensor type. It is necessary to choose a sensor specifically for a warm floor. There are other types, the readings of which are strongly affected by drafts and direct sunlight. As a result, the device will record the temperature of the air, not the floor. There are options for measuring both;

- Installation method.

There are only a few types of sensors:

- The sensor-limiter mainly works on the maximum or minimum temperature, that is, it does not allow the surface to cool or heat up to a certain level. It is usually used when installing cable electric underfloor heating. The sensor-limiter is installed in the insulating pipe.

- Sensors with thermostats are standard and programmable and are sold together with the underfloor heating system.

Many people think that it is not necessary to install a thermostat and a warm sensor. But unfortunately, in the absence of such devices, it will be impossible to control the level of heating. In addition, prolonged operation of underfloor heating leads to excessive consumption of electricity. In addition, there are a number of floor coverings that do not tolerate overheating. For example, the temperature of carpet and laminate should not exceed 30 °C. Otherwise, the material will deform and begin to release substances harmful to human health.

A graph clearly illustrating the operation of a warm floor. As soon as the floor temperature drops to the setpoint, the sensor gives a signal to the thermostat, which turns on the heating. Having reached the upper temperature setting, the sensor-thermostat-heat-insulated floor chain is activated again and the heating is turned off

A graph clearly illustrating the operation of a warm floor. As soon as the floor temperature drops to the setpoint, the sensor gives a signal to the thermostat, which turns on the heating. Having reached the upper temperature setting, the sensor-thermostat-heat-insulated floor chain is activated again and the heating is turned off An important point is that the manufacturers of the "warm floor" system do not provide a guarantee for their products if the temperature sensor and temperature controller are not used.

How to install?

The temperature sensor is mounted next to the thermostat at a distance of 50 cm from the nearest wall. It captures temperature changes, sends a signal to the thermostat, and he already corrects the temperature of the underfloor heating. Therefore, it is very important to correctly install and connect the sensor, because the whole chain of further actions of the device is conducted from it. The installation of the temperature sensor depends on the type of flooring.

Scheme of mounting the sensor and thermostat

Scheme of mounting the sensor and thermostat The sensor for linoleum, parquet, laminate or carpet is a small cylinder that is attached to the end of the cable. It fits into a corrugated tube with a plug at the end, which is fixed in the floor.

Hard floor sensors, such as tiles, are protected by a special gel sheath. It softens mechanical shocks.

The sensor can be laid in a strobe or on the floor surface; it is laid strictly between the heating conductors of the underfloor heating cables

The sensor can be laid in a strobe or on the floor surface; it is laid strictly between the heating conductors of the underfloor heating cables The underfloor heating sensor must be installed between the heating conductors. You can fix it with mounting tape. It is placed in a corrugation and sealed. One end should be near the heating core, and the other should be directed to the thermostat. After that, you can proceed to the connection.

How to connect?

There are two ways to connect a warm floor:

- Straight. The thermostat and heating cable are combined.

- Using a breakout box. The cable runs to this box, and then to the heating circuit.

Auto switches are installed in the electrical panel, and a junction box is attached to the wall, to which wires from the shield are connected. A strobe is laid from the box to the floor itself, and two tubes will be located in it: in one - a heating cable line, in the other - a temperature sensor. After that, you can test the entire system by measuring the resistance. If the system is working properly, the floor covering or screed is laid.

Scheme of connecting a warm floor through a junction box

Scheme of connecting a warm floor through a junction box The main reason for the failure of the "warm floor" system is the breakdown of the thermostat. For diagnostics, it is necessary to measure the resistance between the cable cores. The exact resistance value is indicated in the instructions for the thermostat, but usually it is in the range of 5-30 kOhm. If the resistance values \u200b\u200bare very different from the passport ones, then there is no point in repairing the thermostat and it is better to completely replace it. To do this, you need to write down the model and contact a specialized organization for the sale and repair of such products. It is desirable that the sensor and thermostat are from the same manufacturer. Self-replacement is only possible if the temperature sensor can be removed. If it is built "tightly", then you will have to resort to the help of specialists.

Do not forget that working with a floor heating sensor implies compliance with safety regulations. Before proceeding with the installation and connection of the sensor and temperature controller, the apartment should be de-energized. In addition, you need to know the elementary basics of electrical engineering. If there is no self-confidence, it is better to entrust such an important matter to a professional. Leave comments on the article, share your experience.