K category: Gas supply

Installation of gas appliances

Installation of gas equipment and appliances in place, their connection to gas networks, heating systems and water supply, as well as piping is carried out according to the project.

The room where gas equipment is installed must have natural light and permanent supply and exhaust ventilation. Plates, tagans, water heaters, boilers and heating devices are installed only factory-made. Non-standard gas appliances used in institutions (educational, scientific) are manufactured according to special projects.

Gas stoves and tagans in residential buildings are placed in kitchens with a window with a window or transom, so that their free use is ensured, and also that there is free passage from at least two sides. Do not place slabs near or against windows; when the window is open, the flame can be shifted from the burner. The distance between the gas stove or tagan, counting from the edge of the top of the slab or tagan and the wall, must be at least 5 cm. : for stoves - from the floor, and for tagans - 10 cm below the tagan. In addition, the sheet must protrude beyond the top of the slab or tagan by at least 10 cm in width and at least 80 cm in height.

The passage between the stove and the opposite wall must be at least 1 m. Cooking stoves and tagans are installed strictly horizontally in level, all legs must rest on the floor.

Gas meters in apartments, as a rule, are installed in kitchens at a height of 160-180 cm from the floor to the bottom of the meter; the distance in plan from the meter to the center of the nearest burner of the stove must be at least 80 cm. In this case, the shut-off valve at the stove is installed at a height of 150 cm from the floor.

In modern residential buildings with central heating and a centralized hot water supply system, meters are not installed in apartments.

In the absence of gas meters and only a gas stove is installed, the gas supply pipeline to the stove is located at a distance of 165-170 cm from the floor or laid at the level of the ramp, in this case the shut-off valve is installed at a distance of at least 20 cm to the side of the stove.

In the kitchens of catering units, children's, medical and educational institutions, canteens, restaurants, etc., restaurant-type stoves, digesters and other gas equipment are used for cooking with the removal of combustion products into chimneys.

Particular attention should be paid to the condition of the chimneys. Often they are arranged attached, located on the outside of buildings. Such chimneys must be insulated, otherwise the products of combustion will not be removed from the stove. In addition, fresh air must be supplied to the kitchen room. This is necessary both to improve the working conditions of the maintenance personnel and for the operation of exhaust ventilation systems. If there is not enough supply air, the exhaust systems will take air from the street through the chimney from the gas stove, thereby overturning the draft (chimneys will work not for exhaust, but for inflow). The performance of the ventilation system is 1000 mg/h for every 1 m2 of the stove top.

Rice. 1. Installing a gas stove a - front view; b - side view; 1 - gas riser (option I); 2 - gas riser (option II); 3 - sleeve; 4 - gas coupling tension valve

Gas instantaneous water heaters are installed on fireproof walls (brick, concrete) or on slow-burning walls (wooden plastered). In the latter case, the gap between the water heater and the wall must be at least 3 cm, and the wall section must be upholstered with roofing steel on an asbestos sheet with a thickness of at least 3 mm. The upholstery should extend beyond the water heater on the sides and top by 10 cm and the same distance below the burner. wooden walls, covered with ceramic tiles, do not insulate, but at the same time increase the distance between the wall and the water heater up to 5 cm. It is forbidden to install gas water heaters on wooden unplastered walls, even with fireproof insulation.

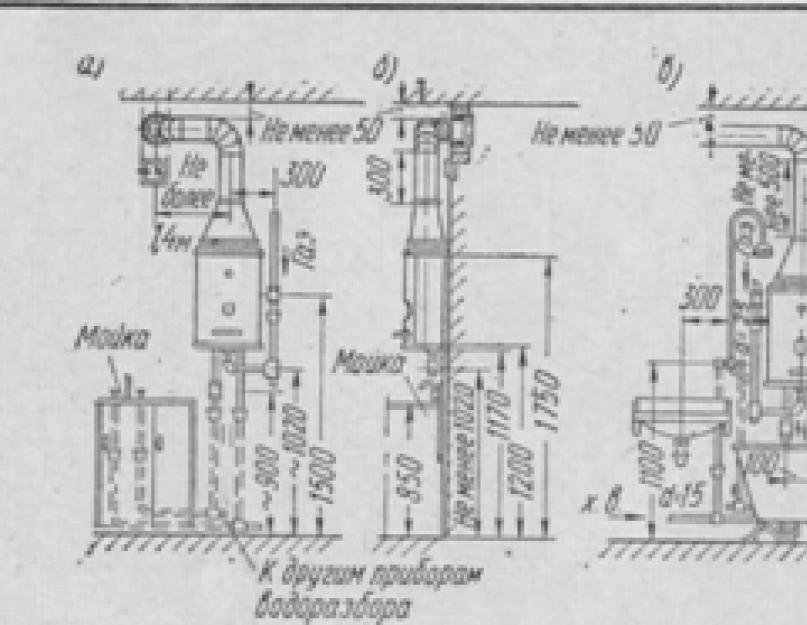

Rice. 2. Installing the water heater KGI-56 o and b-in the kitchen(front view and side view); c and d - in the bathroom (front view and side view)

Gas water heaters are installed so that the distance from the floor to the burner is 90-120 cm. In relation to the bath, it is better to place the water heater on the side of the bath outlet. Gas water heaters are attached to the wall with special hangers - metal strips that are shot or embedded in the wall with cement mortar.

The procedure for installing a gas water heater is as follows: first, they plan the installation location of the column, drill holes, install fasteners; then hang the column and connect it to the gas pipeline and water supply (Fig. 2).

To remove the products of combustion of the gas-air mixture from the gas burner of the water heater, vertical exhaust channels (chimneys) are arranged.

The amount of combustion products in high-speed gas water heaters is so large that gas water heaters are not allowed to be put into operation without their removal into a separate chimney. The bathroom room is usually small, and therefore even a small removal of products of incomplete combustion from a gas water heater into the room can cause serious consequences.

Since all the air required for gas combustion enters the combustion chamber of the water heater from the bathroom, air is supplied to it through the gap between the door and the floor, which is specially provided for this purpose.

The chimney for removing combustion products from a gas water heater must be arranged separately, it has sufficient dimensions and is reliably protected from brick collapses, various blockages and icing.

The most important indicator of the safety control of the operation of a gas water heater is the vacuum in the chimney, which must be at least 0.5 mm of water. Art. Otherwise, due to the release of part of the combustion products into the bathroom, the air in it may be poisoned, which is life-threatening.

Due to the fact that the products of combustion from the gas water heater are discharged into the chimney by a draft interrupter, the latter simultaneously with the products of combustion captures part of the air from the bathroom and ventilates it, while removing excess heat and water vapor. Thus, the traction chopper is a kind of thermal fan.

In existing buildings, it is allowed to connect no more than two water heaters located on the same floor to one chimney. The entry of combustion products into the chimney is arranged at different levels with a distance between them of at least 50 cm. If this cannot be done, the entry is arranged at the same level, but a vertical cut 50-70 cm high is installed in the chimney. solid fuel stoves, they can only be used at different times.

Municipal gas appliances (restaurant stoves, cooking boilers, etc.) are connected to independent chimneys. When using a common chimney for several appliances, combustion products are introduced at different levels or with a cut-off device.

As a rule, chimneys are arranged in the internal main walls of a building with a size of 13X13 cm, a cross-sectional area of \u200b\u200bat least 150 cm2 \\ and they should not have horizontal sections throughout.

In those places where chimneys pass near the wooden elements of buildings, fireproof fireproof cuts are arranged to isolate the wooden elements from exposure to high temperatures. The thickness of the groove from the inner surface of the chimney to the wooden structure is assumed to be 38 cm at the intersection of the interfloor ceiling and 25 cm of the roof.

Chimneys must not be placed on the roof in the zone of wind backwater. In the case when the pipe on the roof is located in close proximity to parts of the building that exceed it in height, blowing into the pipe can occur with a certain wind direction. This will cause a reverse draft, i.e. the draft will be directed through the smoke channel not to the atmosphere, but in the opposite direction - to the bathroom. Therefore, the chimney is taken out 0.5 m above the roof ridge, if it is located no further than 1.5 liters from it. If the pipe is 1.5-3 m away from the roof ridge, it is placed at the level of the roof ridge. In the case when the distance of the chimney to the roof ridge is more than 3 m, the pipe is erected below the roof ridge to a mark that corresponds to a straight line drawn at an angle of 10 ° to the horizon of the ridge. However, in all cases, the pipe must protrude above the adjacent roof surface by at least 0.5 m.

Chimneys end with metal umbrellas that protect them from atmospheric precipitation. Umbrellas are made removable for the possibility of cleaning the pipe.

Gas appliances are connected to chimneys with pipes made of roofing or galvanized steel. The diameter of the connecting pipes must not be less than that of the device nozzle (Fig. 3). For this purpose, corrugated bends with a diameter of 125 mm are used, which serve to remove gases from gas appliances. Branches are made from sheet (roofing) steel using the industrial method on STD-1051 machines.

The value of the vertical section of the connecting pipe, counting from the bottom of the flue pipe of the gas appliance to the axis of the horizontal section of the pipe, must be at least 0.5 m. In rooms up to 2.7 m high, the length of the vertical section is allowed for devices with draft breakers, 0.25 m and for appliances without traction breakers 0.15 m.

The total length of the horizontal sections of the connecting pipes should be no more than 3 m in newly built houses, and no more than 6 m in existing houses. The connecting pipes should have no more than three turns, the radius of curvature of which should be at least the diameter of the pipe.

Rice. 3. Accession of a geyser to the smoke channel 1 - a conical branch pipe; 2 - hatch for cleaning; 3 - pocket; 4 - connecting pipe; 5-limiting washer; 6 - concrete or cement mortar; 7 - wire 0 3 mm; 8 - three turns of asbestos cord

Connecting pipes must have a slope towards the gas appliance of at least 0.01. The suspension and fastening of the connecting pipes must not sag.

The links of the connecting pipes must fit tightly, without gaps, into one another along the gas flow by at least 0.5 of the pipe diameter. The end of the connecting pipe is connected to the smoke channel by pushing it into the masonry by at least 10 cm, it should not protrude beyond the channel wall, for which it is necessary to have restrictive Devices (washer or corrugation).

It is forbidden to lay connecting pipes through living rooms. Connecting pipes laid through cold rooms are insulated. The connecting pipe from the gas appliance is connected to the chimney so that in the latter below the pipe inlet there is a “pocket” with a depth of at least 25 cm, which must have a cleaning hatch. In houses made of panels or blocks, hatches in the channels are not necessary.

As already mentioned, the AGV-80 water heater can be used for hot water supply and heating purposes. In existing residential buildings, stove heating is replaced by central heating, while the AGV-80 water heater serves as the heating boiler for each apartment. When installing AGV-80 on wooden floor under the water heater it is necessary to lay fire insulation from roofing steel on asbestos cardboard measuring 600 × 600 mm. A plug valve must be installed on the gas pipeline in front of the water heater. The main riser of the heating system with a diameter of 1/2 ”is connected to the upper fitting of the water heater. The return line is connected to the lower fitting AGV-80 to the check valve installed on the water line. During the heating season, the water heater operates around the clock and is not turned off at night.

Before installing gas stoves in the room, the installation of clean floors must be completed. The slabs are installed with legs on the floor and rigidly fixed in order to avoid violation of the density of connections with the gas pipeline in case of accidental shift. Fastening is carried out with the help of crutches through the holes in the legs.

Plates are installed vertically. The position of the upper table is checked by level.

Plates are checked before installation. Their upper table should lie on supports without pitching, the pallet should be freely removed and installed in place; burners - fit to the nests without pitching; faucet handles should not leave position 0 without first pressing them along the axis and be sharply fixed in position 0; jamming when turning the handle is unacceptable; the burner body must be freely removable and inserted; displacement of the centers of burners and burners is allowed by ± 10 mm; the distance from the upper surface of the ribs of the burners to the covers of the burners should be within 11-15 mm; nozzles should not have mechanical damage; The oven door must open and close without binding. Being more than half open, the door should smoothly lower under the influence of its own weight to a horizontal position, and in the closed position it should fit snugly against the frame and, when opened at a small angle, be closed under the action of a spring.

Items of oven equipment (brazier, baking tray, etc.) must be removed and installed freely, without jamming; the turning mechanism of the oven burners must work without jamming.

Before installation, the plate is tested for tightness. On the seals, a part for connecting the device to the network is attached to it. The gas water heater is installed above the bath in accordance with the installation position.

The sealing of the threaded joints of the gas pipeline is carried out with flax using red lead, closed on natural drying oil. In Leningrad, for many years now, a special paste has been used, developed by the laboratory of varnishes and paints of the Lensoviet Institute of Technology. The paste consists of divinyl rubber (up to 1%), non-drying mineral oils (24%) and ground chalk (75%). The use of this paste, however, does not preclude the use of flax.

- Installation of gas appliances

Why were the norms for the distance to buildings and objects from the gas pipe invented? Alas, we often neglect the norms of SNIP, especially on household and summer cottages. Especially disregard for the norms in the event that the threat of a fine is unlikely. But is it a penalty?

The norms in which the distance from the gas pipe is prescribed is our own safety. Non-compliance or insufficient compliance can turn into something more terrible than penalties. So is life really worth neglecting these indicators, even if it is not very convenient?

Modern standards are suitable for the design of new gas supply systems, as well as the modernization of existing ones. According to them, the main gas outlets for domestic use do not exceed a pressure of 1.6 MPa. According to the same standards, gas supply is designed in summer cottages and cottage settlements.

These standards are not suitable for gas supply systems of industrial organizations, for example, oil refineries, ferrous metallurgy and others.

Composition of the gas supply system:

- external pipelines;

- internal;

- equipment and units for control, measurement, gas supply, as well as system maintenance.

Position

So, let's talk about the design of systems and the distance of the pipes of the system from various objects.

To do this, we clarify that, according to SNIP, two types of gas pipeline are distinguished:

- underground;

- outer.

Each of the types has its own distance standards, we will consider them in more detail.

Underground

The distance from the house to the gas pipe in the embankment cannot be less than 5 m. There are special provisions of the SNIP, according to which the distance can be reduced by 50%, but they are regulated by the terrain and the passage of the gas pipeline. For example, laying pipes between houses, arches, in very limited areas, etc.

The distance to the gas pipe of the outer walls of the well, chambers or other equipment of engineering networks should not be less than 30 cm. The laying must be carried out in compliance with the technical requirements and conditions. Only this can be a guarantee of security. By the way, that is why an independent transfer or organization of a gas supply system is not allowed.

The distance to air communication lines, as well as external electrical networks, cannot be less than 2 meters. The same applies to the gap between the gas pipeline and the heat transfer channels. The distance from the gas pipe to the fence, taking into account the underground laying of the highway in the villages, should be at least 50 meters. SNIP provides for a reduction in the gap, but only when taking into account certain norms prescribed in the regulations.

The depth of laying the gas pipeline should exceed 0.8 m for roads and roads with heavy passenger traffic and 0.6 m for roads with low traffic.

Ground and elevated

Aboveground wires are laid along the facades of buildings, on special supports made of materials that do not burn.

The place of laying depends on the pressure of the gas pipeline:

- up to 0.6 MPa - wiring is allowed on shelves and overpasses, as well as columns, supports and along the walls of industrial buildings;

- up to 0.3 MPa - it is allowed to lay on the walls of residential buildings and public buildings not lower than the 3rd degree of fire resistance.

It is forbidden to lay gas pipelines of any pressure for the purpose of gas transit, according to SNIP:

- on the walls of kindergartens and schools, hospitals and companies that involve a large crowd of people;

- for buildings in which the walls consist of panels and have metal sheathing with polymer insulation;

- for buildings of category "A" and "B".

It is prohibited to conduct medium and high pressure gas pipelines along the walls of residential buildings. It is also impossible to conduct a transit gas pipeline through window openings.

In areas near the ground, the pipes must be enclosed in a special case. The distance to the gas pipe from the ground horizontally cannot be less than 35 cm.

The distance from the gas pipe to the chimney must be more than 2 meters from the outside and at least a meter from the inside of the building. However, this indicator depends on many factors, for example, location, conditions of gas wiring and pipe configuration, etc.

In room

It is very important to comply with the technical conditions in the room, since often the cause of emergency situations with gas is precisely household non-compliance. In most cases, in apartments and private houses, polyethylene pipes of the gas pipeline are used. Usually they go exclusively to a gas stove or oven. But in some houses there is an autonomous gas heating. And here a special boiler is already used.

In this case, the floor from the pipe must be at least 50 cm away. The same distance is from the wall to the boiler. The vertical distance to the chimney should not be less than 80 cm inside. The same distance of the pipe to the stove for cooking. The distance from the pipe to the outlet in a small room should not be less than 30 cm.

To secure a building means to secure life. That is why it is important to follow the rules and regulations specified in the SNIP.

Page 29 of 41

METER LOCATION

6.45 It is recommended to install devices (assemblies) for measuring gas consumption:

In a gasified room;

In non-residential premises of a gasified residential building with natural ventilation;

In the adjacent to the gasified room and the open opening connected to it in the production building and the boiler room;

In hydraulic fracturing, ShRP, GRPB;

outside the building.

6.46 As gas metering devices, it is allowed to use household gas meters (hereinafter referred to as meters), the placement of which is regulated by this subsection.

6.47 The installation of meters is provided based on the conditions for the convenience of their installation, maintenance and repair. The installation height of meters, as a rule, should be taken as 1.6 m from the floor level of the room or the ground.

6.48 In order to prevent corrosion damage to the meter coating during its installation, a gap (2-5 cm) should be provided between the meter and the structure of the building (structure) or support.

6.49 The installation of the meter indoors is envisaged outside the zone of heat and moisture release (from the stove, sink, etc.) in naturally ventilated places. It is not recommended to install meters in stagnant areas of the room (areas of the room fenced off from the ventilation duct or window, niches, etc.).

I accept the distance from the installation sites of the meters to the gas equipment! in accordance with the requirements and recommendations of manufacturers, set out in the passports of the meters. In the absence of the above requirements in the passports, the placement of meters should be provided, as a rule, at a distance (along the radius) of at least:

0.8 m from a household gas stove and gas-using heating equipment (capacitive and instantaneous water heater, boiler, heat generator);

1.0 m from the restaurant stove, digester, heating and heating-cooking stove.

6.50 Outdoor (outside the building) installation of the meter is provided under a canopy, in cabinets or other structures that provide

SP 42-J 01-2003

protection of the counter from external influences. Open installation of the counter is allowed. The placement of the counter includes:

On a separate support on the territory of the gas consumer;

On the wall of the gasified building at a horizontal distance of at least 0.5 m from door and window openings.

Placing counters under openings in the walls is not recommended.

6.51 The design of the cabinet for placing the meter must provide natural ventilation. Cabinet doors must have locks.

| Content |

|---|

Wall-mounted gas boiler of closed type 24 kW. At what distance from the side wall should the boiler be hung? What SNiP are we guided by in 2015

Good question, thanks. There are a lot of misconceptions on the Internet on this topic, it will be useful to understand.

“What SNiP are we guided by in 2015”? Oddly enough, none, if we are talking about the Russian Federation. In the good old SNiP 2.04.08-87, which was in force in various editions until 2002, the following was written in the “Gas supply of residential buildings” section:

We see that the distance between the gas wall-mounted boiler and the wall is 10 cm, provided that it is made of non-combustible materials. However, the SNiP of 87 has become invalid and today SP 62.13330.2011 is in force instead. The new rules do not even mention the distance between the boiler and the wall. There is logic in this, because modern gas heat generators are very different from those that were produced a quarter of a century ago. The body of boilers with a closed combustion chamber heats up much less. The only document that today can be unambiguously relied upon is the instruction for the installation and operation of a gas boiler. And for each boiler model, the manufacturer indicates individual data, for example:

Bosch wall-mounted boilers of the Gaz 7000W series, both with closed and open combustion chambers, should be located no closer than 10 cm from the wall, as in the old Soviet norms

Beretta boilers of the Ciao series must not be hung closer than 3 cm from the side wall

Buderus Logamax plus can be mounted close to the wall

Everything is clear - we strictly follow the instructions. But occasionally there are wall-mounted gas boilers, in the manuals for which there is no indication of the minimum required distance to the wall at all. In this case, for boilers with a closed combustion chamber, we advise you to focus on the provision of the Joint Venture on the need to ensure convenient maintenance of the thermal unit. The boiler casing must be freely dismantled. You will have to study the design of the boiler. On some models, to remove the cover, you need to unscrew a few screws on the side. This means that you should leave a space to the wall sufficient to fit a screwdriver, about 15 cm. Boilers for which the distance is not indicated, we recommend hanging at least 10 cm from the wall, even if this is not necessary for maintenance. It will be easier to arrange commissioning, the inspector will not have any questions.

However, it should be borne in mind that individual regions have the right to adopt their own regulations (instructions) that partially replace federal norms. We are not aware that today regional regulations limit the distance from the boiler to building structures, but we still recommend that you consult your local branch of the Ministry of Gas just in case.

The widespread opinion that the owner of a dwelling can do whatever he wants in it is wrong. This is especially important when it comes to high-risk household equipment. The procedure for handling it is strictly regulated, and violations can lead to many undesirable consequences from a fine to an accident.

Can I install a gas stove myself? Yes, if it's only about placement in the kitchen. The connection process must be performed by a certified service. The installation of gas stoves in an apartment or a private wooden house without complying with the requirements of regulatory documentation entails the issuance by representatives of the resource supply organization of an order to eliminate violations and a possible shutdown of the gas supply before it is completed.

Do-it-yourself gas stove installation

The answer to the question of whether it is possible to install a gas stove on your own is given by the order of the Ministry of Regional Development No. 239 and a standard gas supply agreement concluded between the regional representative office and the subscriber.

According to the requirements of the law, connection to the intra-house network is carried out by a specialized gas distribution organization engaged in the maintenance and repair of in-house or in-house gas-using equipment. The obligations of the subscriber specified in the contract include timely notification of the supplier about the update of equipment.

Breach of contract allows the supplier to unilaterally suspend or restrict supply. In case of installation errors, the one who installed the gas stove in an apartment or private house on his own will be responsible for the consequences of incorrect connection, including accidents or emergencies.

When figuring out whether it is possible to install a gas stove yourself, you need to pay attention to one more important point. In case of unauthorized connections, the manufacturer is not responsible for the safety of using the equipment and disclaims warranty service obligations.

Rules for installing a gas stove in the kitchen in the apartment

The rules for installing household gas stoves in the kitchen in an apartment are specified in building codes and rules SP 42-101.

- The height of the room at the location of the equipment should be at least 2.2 m in the presence of straight and sloping ceilings.

- The allowable number of burners is determined based on the volume of the kitchen and the calculation of 4 m 3 per burner.

- The minimum distance to walls, internal partitions and kitchen furniture should be in accordance with the manufacturer's recommendations.

- Installation can be carried out at building structures made of non-combustible and combustible materials (subject to protective insulation).

In addition to natural ventilation room, it is recommended to install an exhaust hood for reliable removal of combustion products.

Installation of a gas stove in a private house

As is the case with kitchens in an apartment, installing a gas stove in a wooden house has its own rules. Even wood treated with flame retardants is a moderately combustible material. If the house is built using concrete or other non-combustible materials, the regulations remain the same, since the environment may ignite. For engineering systems of private and suburban single-family houses, SNiP 31-02 apply.

Gas stove installation standards regulate the distance between the top of the appliance and the wall, as well as the type of fire retardant coating. For this reason, the slab is located at least 10 cm from the building structure, which must be plastered or sheathed with galvanized steel on asbestos sheet.

Also, according to the requirements for installing a gas stove, it can be located in the summer kitchen or under a canopy while protecting the burners from blowing out. This allows you to use the equipment in the country during seasonal residence or in the absence of capital housing.

General requirements for installing a gas stove

It is dangerous to install a gas stove with your own hands, not only because of the lack of specialized knowledge, but also because of the risk of missing important points:

- Before connecting, it is necessary to check whether the type and pressure of the gas in the line correspond to the parameters indicated on the plate located on the rear surface of the stove or in the warranty card.

- If it is necessary to change the type of connection from natural gas to a liquefied mixture, the transfer is carried out by the same people who install the gas stove in the apartment - the personnel of a specialized organization.

- The stove with an electric oven is connected to a single-phase network and connected to a socket with a grounding contact.

- Before starting work, the gas supply is shut off, after installation, the tightness of the connections is checked.

- The stove is not connected to the chimney and is not placed on stands.

- The floor elements of the kitchen set (cabinets, countertops) are located below the level of the burners.

How to install a gas stove in the kitchen: choosing a location

Is it possible to install a gas stove in the kitchen yourself, and how to do it correctly, is detailed in the instruction manual.

The device is installed horizontally and leveled using adjustable feet, remaining stationary after connection and moving only to check the tightness of the connections. Furniture, kitchen equipment, textiles and interior items are placed at a safe distance to prevent accidental ignition.

Installation of a gas stove is carried out using a flexible connection. After connection, the hose or sleeve should not experience mechanical stress - stretch, pinch or bend. It is located so as not to come into contact with the back wall of the appliance, which becomes very hot during operation of the oven, and does not create difficulties during inspection.